What is a Table Top CNC Machine? Benefits, Uses, and Buying Guide

In the rapidly evolving world of manufacturing and design, the versatility and accessibility of a table top CNC machine has become a game-changer for both hobbyists and professionals alike. According to renowned CNC expert John Smith, “The table top CNC machine democratizes the fabrication process, making it achievable for almost anyone to turn their ideas into tangible products.” This technology allows for computer-controlled precision cutting, milling, and engraving, empowering users to create intricate designs that were once limited to large industrial machines.

The benefits of using a table top CNC machine extend beyond just precision; they encompass ease of use, space efficiency, and affordability. Whether you're a small business owner looking to enhance production capabilities or an individual passionate about woodworking or metalworking, a table top CNC machine can cater to a wide range of applications. Its compact design fits seamlessly into any workspace, while still delivering professional-quality results that can elevate projects to a new level.

Understanding the various uses and features of a table top CNC machine is crucial for making informed purchasing decisions. As the demand for customization and quality continues to rise, this technology offers an invaluable tool for anyone seeking to innovate and create. Whether you’re venturing into the world of CNC for the first time or looking to expand your existing capabilities, understanding the core benefits and functionalities of a table top CNC machine is essential for success in today's manufacturing landscape.

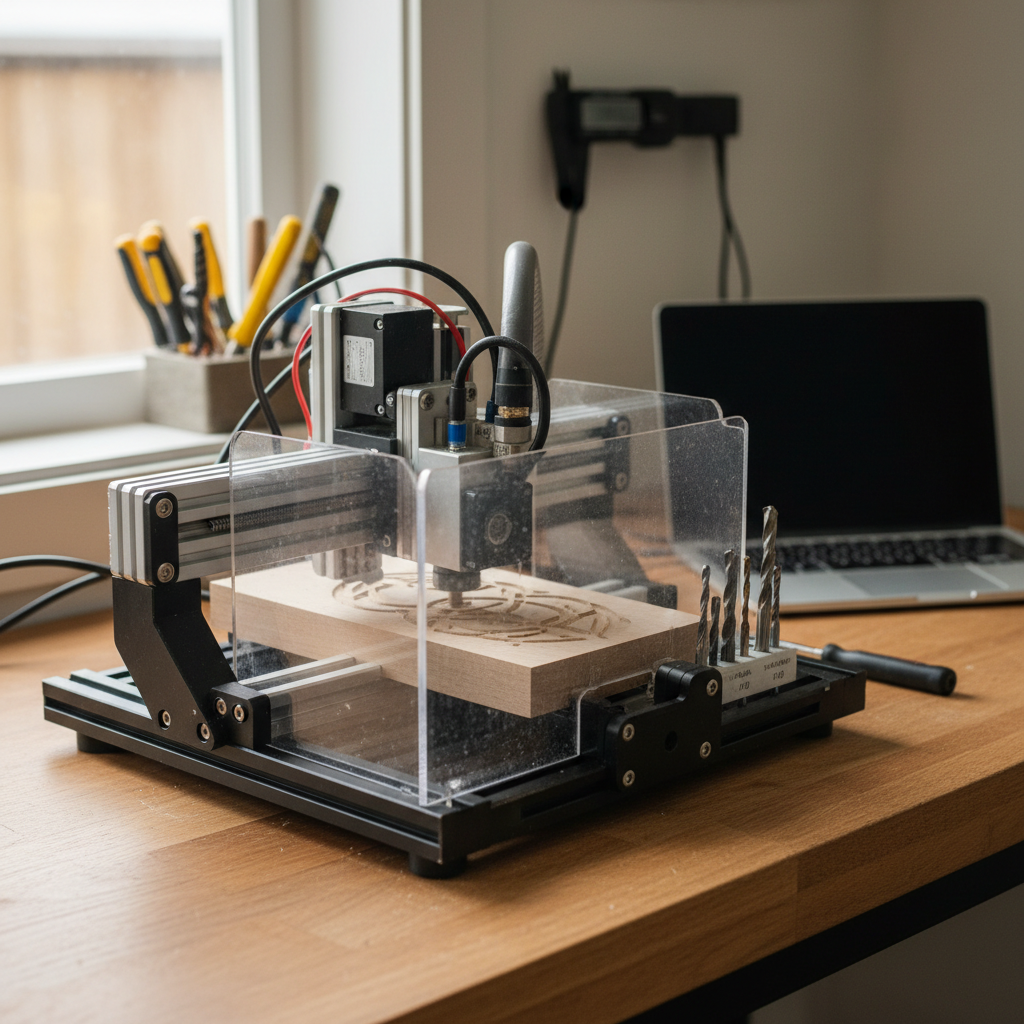

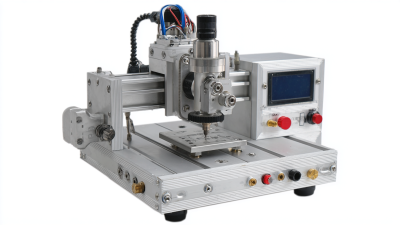

Understanding Table Top CNC Machines: An Overview of Their Design and Functionality

Table top CNC machines are compact, versatile tools designed for precision cutting, milling, and engraving across various materials like wood, metal, plastic, and foam. The key feature of these machines is their size, making them ideal for small workshops, hobbyists, and educational institutions. Despite their reduced footprint, they offer powerful capabilities comparable to larger CNC machines, providing users with an efficient way to create intricate designs and prototypes.

The design of a typical table top CNC machine includes a rigid frame that supports the moving components, which ensure stability during operation. These machines can be equipped with various spindle options, enabling different machining processes. Additionally, many models come with user-friendly software, making programming and operation accessible even to beginners.

The integration of advanced features like automatic tool changers and enhanced motion control systems further enhances their functionality, allowing for seamless production of complex parts. This combination of compact design and advanced technology makes table top CNC machines an essential tool for both professionals and enthusiasts looking to harness the power of computer numerical control in their projects.

Key Benefits of Table Top CNC Machines for Hobbyists and Professionals

Table top CNC machines have become increasingly popular among both hobbyists and professionals due to their versatility and compact design. One of the primary benefits is their ability to produce intricate designs with high precision. Hobbyists can create personalized items, prototypes, or intricate models without needing access to larger industrial machines. This precision allows for a level of detail that enhances creative projects and transforms ideas into tangible realities.

For professionals, table top CNC machines offer efficiency and cost-effectiveness. With the ability to automate processes, businesses can reduce labor costs and increase production speed. These machines are also ideal for small-scale operations, allowing startups and artisans to maintain high-quality outputs without the financial burden of larger equipment. Furthermore, their ease of use and accessibility make them an attractive option for those looking to expand their capabilities, whether for crafting unique products or refining manufacturing processes.

What is a Table Top CNC Machine? Benefits, Uses, and Buying Guide

| Feature | Description | Benefits | Typical Users |

|---|---|---|---|

| Size | Compact design for small workspaces | Saves space | Hobbyists, small business owners |

| Material Compatibility | Can handle wood, plastic, and metals | Versatile for different projects | Craftsmen, engineers |

| Ease of Use | User-friendly software interfaces | Quick learning curve | Students, hobbyists |

| Cost | Affordable compared to larger CNC machines | Low entry cost for new users | Startups, hobbyists |

| Precision | High accuracy with intricate designs | Allows for detailed work | Artists, designers |

Popular Applications of Table Top CNC Machines in Various Industries

Table top CNC machines have found their place across various industries thanks to their versatility and compact size. From woodworking to medical research, these machines enable precise fabrication and prototyping, significantly enhancing productivity. For instance, in the woodworking sector, they facilitate intricate designs and custom projects, leading to increased demand for skilled artisans. Moreover, in medical applications, these machines have proven crucial for creating custom implants and surgical tools, advancing the healthcare sector.

When considering the adoption of a table top CNC machine, it is essential to evaluate your specific needs and the types of materials you'll be working with.

Tips for selecting the right machine include:

- Assessing the machine's compatibility with various materials

- The availability of software tools for design

- The level of customer support from the manufacturer.

Additionally, keep an eye on the machine's operational efficiency and the learning curve associated with its use.

With advancements in technology, newer models are also offering features such as AI integration, which can enhance both functionality and ease of use. For those in the manufacturing and creative industries, investing in a table top CNC machine not only streamlines operations but also opens up myriad possibilities for innovation and design.

Essential Features to Consider When Choosing a Table Top CNC Machine

When choosing a table top CNC machine, several essential features should guide your decision-making process. First and foremost, consider the machine's working area. A larger workspace allows for more significant projects, while a compact design suits smaller tasks. It's important to assess how the machine's dimensions will fit into your workspace and accommodate your project needs.

Another critical feature is the spindle power. A more powerful spindle enhances cutting capabilities and speeds, allowing you to work with a variety of materials more effectively. Additionally, look into the machine's software compatibility; a user-friendly interface that supports various design files will make the operation smoother and more efficient.

**Tips**: Before finalizing your purchase, check for community support and available resources. A strong user community can provide guidance and troubleshooting assistance. Additionally, consider machines that offer future upgrade options, ensuring that your investment grows with your skills and project demands. Always read reviews from other users to gauge reliability and performance effectively.

Table Top CNC Machine Usage Across Industries

A Step-by-Step Buying Guide for Selecting the Right Table Top CNC Machine

When considering the purchase of a tabletop CNC machine, a structured approach can significantly enhance your decision-making process. Start by assessing your specific needs, whether it's for woodworking, metalworking, or creating prototypes. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117 billion by 2025, reflecting a growing interest in versatile manufacturing tools. Identifying your material requirements and desired precision will help narrow down your options effectively.

Next, consider the machine’s specifications, such as spindle speed, bed size, and the type of software it supports. A 2022 study by ResearchAndMarkets indicates that machines with high spindle speeds (over 10,000 RPM) can dramatically increase productivity and aesthetic quality in finished products. Furthermore, investigate user reviews and expert insights to understand the reliability and support available for each model. With a range of prices from entry-level to high-end machines, knowing your budget and exploring financing options will also be key in selecting the right machine for your workshop.

Related Posts

-

Navigating Global Trade Standards for Best Desktop CNC Machine Import and Export

-

Top 5 Table Top CNC Machines for Precision Engineering in 2023

-

Top Strategies for Maximizing Efficiency with Desktop CNC Mills in Modern Manufacturing

-

Unlocking Creative Manufacturing with Best Desktop CNC Applications and How to Get Started

-

Exploring the Versatility of CNC Routers: Innovations in Crafting and Manufacturing

-

Exploring Innovations in Portable CNC Machines at the 138th Guangzhou Trade Fair 2025

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information