The Ultimate Guide to Choosing the Right CNC Routers for Woodworking Projects

As the woodworking industry continues to evolve, the use of technology such as CNC routers for woodworking has significantly transformed how artisans and manufacturers approach their projects. According to a recent report by Grand View Research, the global CNC router market is projected to reach USD 2.75 billion by 2025, indicating a compound annual growth rate (CAGR) of 5.8%. This surge in demand highlights the critical role of CNC routers in enhancing precision, efficiency, and creativity in woodworking. For both hobbyists and professionals, selecting the right CNC router is paramount to meeting specific project requirements, optimizing workflow, and ultimately achieving superior craftsmanship. In this guide, we will explore various types of CNC routers available today, along with key factors to consider when choosing the perfect machine for your woodworking needs.

Factors to Consider When Selecting CNC Routers for Woodworking Projects

When selecting CNC routers for woodworking projects, several key factors should be considered to ensure you choose the right machine for your needs. First, the size of the work area is crucial. Depending on the type and scale of projects you undertake, whether it’s small intricate pieces or larger furniture items, you’ll need a router that can accommodate your largest workpieces without compromising precision.

Another important factor is the spindle power and speed. Different woodworking materials require varying levels of power and speeds for optimal cutting performance. A router with a higher spindle power can handle denser woods more effectively, while adjustable speed settings allow for versatile applications, from rough cutting to fine detailing. Additionally, consider the machine's software compatibility and ease of use, as user-friendly interfaces can significantly enhance your workflow and creativity in CNC machining.

Understanding Different Types of CNC Routers and Their Applications

When it comes to woodworking projects, choosing the right CNC router is crucial for achieving precision and quality. Understanding the different types of CNC routers available in the market is the first step in making an informed decision. There are primarily three categories of CNC routers: entry-level, mid-range, and professional-grade machines.

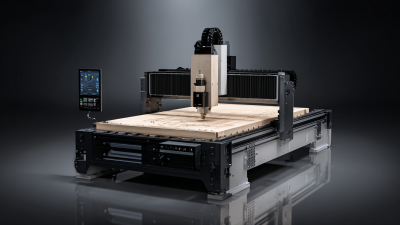

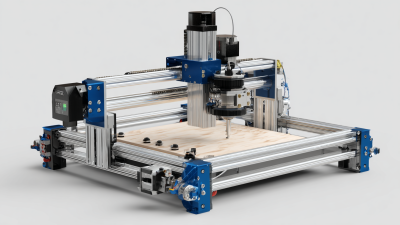

Entry-level routers are ideal for hobbyists or beginners looking to explore woodworking without a hefty investment. Mid-range options offer a balance of performance and cost, suitable for small businesses or serious enthusiasts. Professional-grade CNC routers provide advanced features and capabilities, catering to heavy-duty commercial applications.

Each type of CNC router has unique applications based on its specifications. For instance, entry-level routers may be suitable for smaller projects like signage or decorative items, while mid-range CNC routers can handle furniture making and cabinetry. Professional-grade routers are designed for high-volume production and can work with a wider variety of materials, enabling operations like intricate carvings or complex designs.

As the global CNC machine market continues to grow, with a projected compound annual growth rate of 9.9%, selecting the right router tailored to specific woodworking needs will become increasingly vital for both budding and established woodworkers.

Key Technical Specifications for Optimal CNC Router Performance

When selecting a CNC router for woodworking projects, understanding the key technical specifications is essential for optimal performance. One of the foremost considerations is the spindle power. A higher wattage spindle can handle tougher materials and larger cuts, ensuring smoother operation and reducing wear. Look for a router with at least 2.2 kW power for serious woodworking applications, as this provides the torque needed for intricate designs.

Another crucial specification is the router's cutting area. This refers to the maximum dimensions of the material you can work with, and it directly impacts the scale of your projects. Make sure you choose a CNC router that offers a cutting area suitable for your most ambitious woodworking plans. Additionally, consider the machine’s rigidity and frame construction, as these factors will affect stability and precision during cutting.

Tip: Before making a purchase, try to observe the machine in action if possible. This allows you to assess its speed and accuracy firsthand, which are equally important for achieving high-quality results in your woodworking endeavors. Always consult user reviews and seek out recommendations from experienced woodworkers to make an informed choice.

Maintenance Tips to Extend the Life of Your CNC Router

Maintaining a CNC router is essential for ensuring optimal performance and longevity, especially in woodworking projects. One of the most critical aspects of maintenance is regular cleaning. Dust and debris can accumulate in the machine's moving parts, leading to inefficiencies and potential malfunctions. After each use, take the time to clean the workspace and remove any wood shavings or particles that may have settled on the router. Additionally, lubricating the moving parts with appropriate oils will help minimize friction and wear over time.

Another vital maintenance tip is to regularly check and calibrate the machine. Keeping the CNC router properly calibrated ensures accuracy in your woodworking projects. Regularly inspect the belts and pulleys for any signs of wear and replace them as necessary. Moreover, updating the firmware can improve performance and fix bugs, providing smoother operation. By committing to these maintenance practices, you can prolong the life of your CNC router and enhance your woodworking outcomes.

Cost-Benefit Analysis: Investing in Quality CNC Routers for Woodworkers

When investing in CNC routers for woodworking projects, a cost-benefit analysis is essential for discerning woodworkers. A quality CNC router can significantly enhance productivity and precision, which often translates to higher-quality outputs. According to a report by the Freedonia Group, the demand for CNC routers is projected to grow at a compound annual growth rate (CAGR) of 4.5% through 2025, driven by advances in automation and an increasing number of custom woodworking applications. This suggests that investing in high-quality equipment now can pay off in the long run.

Moreover, a study conducted by Technavio indicates that companies utilizing CNC technology can reduce production time by 30% compared to traditional woodworking methods, directly affecting profitability. The initial expenditure on a robust CNC router can range from $3,000 to over $10,000; however, the decrease in labor costs and improved efficiency makes it a worthwhile investment. By leveraging quality CNC routers, woodworkers not only enhance their craft but also position themselves competitively within a rapidly evolving market that places high value on speed and accuracy.

Related Posts

-

Exploring the Unique Features and Applications of Various CNC Router Machine Alternatives

-

Exploring Examples of the Best CNC Wood Router Machines for Global Buyers

-

Unlocking Precision in Manufacturing with Best Desktop CNC Tutorials for Global Buyers

-

Craftsmanship Meets Innovation: The Best Home CNC Machines from China for Global Solutions

-

Discover the Finest Portable CNC Machines from China's Leading Manufacturers

-

Solutions for Enhancing Production Efficiency with the Best CNC Engravers in 2023

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information