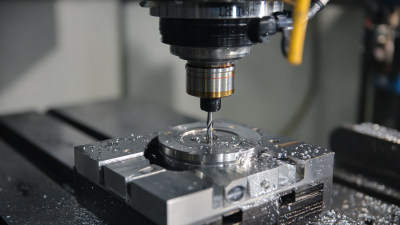

Why Choose a Desktop CNC Mill for Your Home Workshop Projects?

In recent years, the popularity of desktop CNC mills has surged among hobbyists, entrepreneurs, and small workshop owners. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117 billion by 2025, driven largely by the increasing demand for precision in manufacturing and the growing trend of DIY projects. This surge underscores the shifting landscape of home craftsmanship, where sophisticated technology like desktop CNC mills has become accessible to individuals seeking to elevate their creative projects.

A desktop CNC mill offers a unique blend of precision, affordability, and versatility, making it an invaluable tool in any home workshop. With capabilities to produce intricate designs and replicate parts with high accuracy, these machines are not just beneficial for seasoned professionals but also novice makers eager to explore machining. As the trend towards automation and digital fabrication grows, having a desktop CNC mill can empower DIY enthusiasts to turn their ideas into tangible products, fostering innovation and personal expression in the process.

Moreover, the convenience of a desktop CNC mill allows for projects ranging from woodworking to metalworking, embodying a comprehensive solution for various materials and applications. By investing in such equipment, individuals can not only enhance their skillsets but also tap into the burgeoning market for custom creations, thereby transforming their workshops into productive and creative spaces.

Benefits of Using a Desktop CNC Mill in Home Workshops

Desktop CNC mills have become increasingly popular in home workshops, offering a range of benefits that cater to hobbyists and professionals alike. One of the primary advantages of using a desktop CNC mill is precision. According to a recent industry report, CNC machines can achieve tolerances of up to 0.001 inches, which is significantly higher than manual milling methods. This level of precision allows users to create complex parts and prototypes that can enhance their projects and skills.

Another noteworthy benefit is the versatility of desktop CNC mills. These machines can work with various materials such as wood, metal, and plastics, making them suitable for a wide array of applications. Reports indicate that the desktop CNC market is expected to grow at a compound annual growth rate (CAGR) of over 14% from 2021 to 2026, highlighting an increasing trend in their adoption for personal use.

**Tip:** When selecting a desktop CNC mill, consider the size of your workshop and the projects you plan to undertake. Compact models can efficiently fit into smaller spaces while still delivering high performance.

**Tip:** Keep in mind the software compatibility of your CNC mill. Many units come with user-friendly interfaces and tutorials, which can significantly reduce the learning curve for newcomers to CNC machining.

Why Choose a Desktop CNC Mill for Your Home Workshop Projects?

| Benefits | Description |

|---|---|

| Precision & Accuracy | Desktop CNC mills provide high precision, making them suitable for intricate designs and detailed projects. |

| Space-saving | Their compact size allows them to fit easily into small workshops, ideal for home use. |

| Ease of Use | Most desktop CNC mills come with user-friendly software, making them accessible to beginners. |

| Versatility | They can handle various materials including wood, plastic, and aluminum, suitable for diverse projects. |

| Cost-effective | Generally, they are more affordable compared to larger CNC machines, making them a good option for hobbyists. |

| Low Maintenance | Desktop CNC mills require minimal maintenance, reducing the time and cost associated with upkeep. |

Key Features to Look for in Desktop CNC Mills

When considering a desktop CNC mill for your home workshop, it's essential to focus on key features that can enhance your project outcomes. One significant aspect is precision; look for mills that offer high accuracy and reliability in machining. According to industry reports, the global CNC machine market is set to grow from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, reflecting the rising demand for technologically advanced milling solutions. Desktop CNC mills are designed to meet this growing need with advanced capabilities, such as 4-axis machining, which allows for complex designs that traditional routers struggle to handle.

Another vital feature is ease of use. Many modern desktop CNC mills incorporate user-friendly interfaces and software compatibility, ensuring that both beginners and experienced makers can operate them efficiently. As the tabletop CNC milling machines market is projected to reach USD 821 million by 2034, the emphasis on user accessibility continues to shape product development. Additionally, compact designs are a must-have; with space often at a premium in home workshops, these machines provide a perfect balance of size and functionality, enabling makers to tackle a variety of materials with minimal footprint.

Common Materials for Projects with Desktop CNC Mills

When utilizing a desktop CNC mill in your home workshop, the choice of materials is crucial to achieving successful results in your projects. Common materials for machining include wood, plastic, and aluminum. Wood is particularly favored for its ease of use and versatility. It allows for intricate carvings and designs while providing a forgiving medium for beginners. Various types of wood, from soft pine to hardwoods like oak and walnut, can be used, depending on the project’s requirements.

Plastic materials, such as acrylic and PVC, are also popular among hobbyists. They offer a smooth finish and can be easily cut to shape using CNC mills. Acrylic, with its transparent properties, can be crafted into stunning visual designs, making it ideal for decorative projects. On the other hand, aluminum is preferred for more advanced projects requiring durability and strength. Although machining aluminum can be more challenging, it results in high-quality, long-lasting components suitable for functional applications. Each material presents unique characteristics that can influence the outcome of your projects, allowing for a diverse range of creative possibilities.

Setting Up and Maintaining Your Desktop CNC Mill

Setting up and maintaining a desktop CNC mill in your home workshop can greatly enhance your project capabilities. According to a report by Technavio, the global CNC machine market is projected to grow at a compound annual growth rate (CAGR) of over 6% from 2022 to 2026. This growth is largely driven by the increasing demand for precision engineering and customization in manufacturing. For hobbyists and professionals alike, a desktop CNC mill offers an affordable entry point into this high-precision field, enabling users to create intricate designs with ease.

Proper maintenance of your CNC mill is crucial for ensuring optimal performance and longevity. Regular lubrications and inspections can prevent wear and tear, extending the tool's life significantly. Research from the Manufacturing Institute indicates that machines that are routinely maintained can experience up to 20% less downtime. Additionally, using quality software for design and operation, such as Fusion 360 or Vectric, can streamline the workflow, allowing users to maximize their productivity. By adopting these best practices, you can enjoy the full benefits of your desktop CNC mill while achieving outstanding results in your workshop projects.

Exploring Project Ideas for Your Desktop CNC Mill

The rise of desktop CNC mills has revolutionized home workshops, empowering hobbyists and professionals alike to create intricate designs with precision. Projects that can be tackled with a desktop CNC mill are virtually limitless. From custom woodwork and intricate metal components to 3D prototypes and artistic pieces, the capabilities of these machines can cater to various interests. According to a report by Allied Market Research, the global CNC machine market is expected to reach $117 billion by 2027, illustrating the growing interest in CNC technology among makers and builders.

When it comes to project ideas, consider crafting personalized items, such as custom signs, coasters, or even intricate jewelry designs. The ability to produce high-quality, repeatable parts makes desktop CNC mills a great asset for entrepreneurs looking to establish small-scale production lines. Moreover, educational institutions are increasingly adopting these tools for teaching design and engineering, highlighting their versatility in practical applications.

**Tip:** Before starting a project, always ensure your design is optimized for CNC machining; rasterized files or overly complex designs can lead to poor outcomes.

**Tip:** Experiment with different materials; many mills can cut softwoods, hardwoods, plastics, and even aluminum, allowing for diverse project possibilities.

Related Posts

-

Future Trends in Global CNC Machinery Market Leading to the Best Home CNC Machine of 2025

-

Unlocking Creative Manufacturing with Best Desktop CNC Applications and How to Get Started

-

Solutions for Enhancing Production Efficiency with the Best CNC Engravers in 2023

-

Understanding Global Manufacturing Standards for Best CNC Milling Processes

-

Unlocking Precision in Manufacturing with Best Desktop CNC Tutorials for Global Buyers

-

Navigating Global Trade Standards for Best Desktop CNC Machine Import and Export

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information